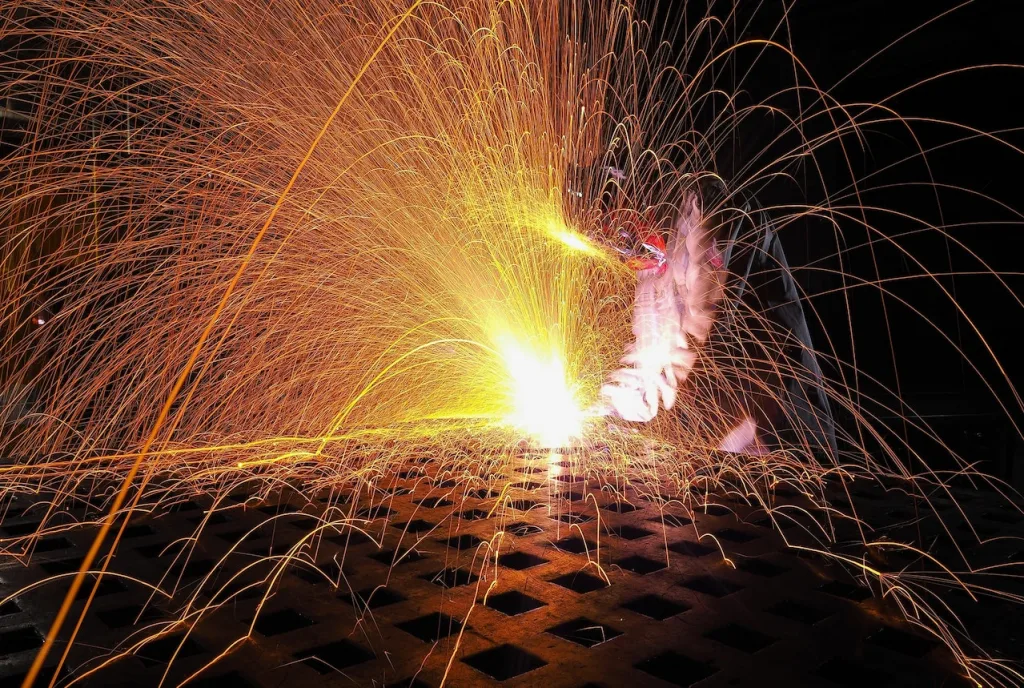

MIG and TIG Welding Services for Steel, Aluminum and Stainless Steel

Nortech’s expertise in the material handling business often connects in the welding processes in order to create a finished product. Nortech offers both (Metal Inert Gas) MIG and TIG (Tungsten Inert Gas) welding services for steel, aluminum and stainless steel. We are dedicated to producing quality workmanship provided by our expertly trained employees.

MIG Welding

MIG welding involves a wire-fed consumable electrode that is continuously pushed through a nozzle. This works using a spoon gun that feeds the wire electrode at a constant speed, which will deposit filler metal onto the parent material. The ease of use and speed of the application benefit MIG welding greatly. Compared to TIG welding, MIG is much quicker with a lower operating cost. The downside of MIG welding is the involved setup and clean up process.

TIG Welding

TIG welding is the more difficult of the two, but has a more aesthetically pleasing technique to master. It differs form MIG welding in that TIG uses a non-consumable tungsten electrode. The tungsten electrode will heat the parent metal and a filler rod. The operator holds both the filler rod and torch, and will use their feet to control the heat with a pedal. TIG has the cleanest and nicest looking welding technique which greatly reduces clean up time. The welds also boast a stronger and higher quality weld than the MIG weld. The downside of TIG is that it is significantly slower than MIG and requires a clean welding surface which leads to a higher operating cost.